Fit for purpose. Do it right the first time. If the walls in the quality department at M.R.S. Machining had ears, this is what they would hear. We take on the responsibility of ensuring that quality is built into the manufacturing process of the part. With an M.R.S.-machined part, you get the full package; thoughtful planning, expert machining, and strict quality standards. We have provided the table of contents from our quality manual below to give you an idea of what types of things we look for when determining whether a part is ready for delivery.

Our Quality Control Equipment

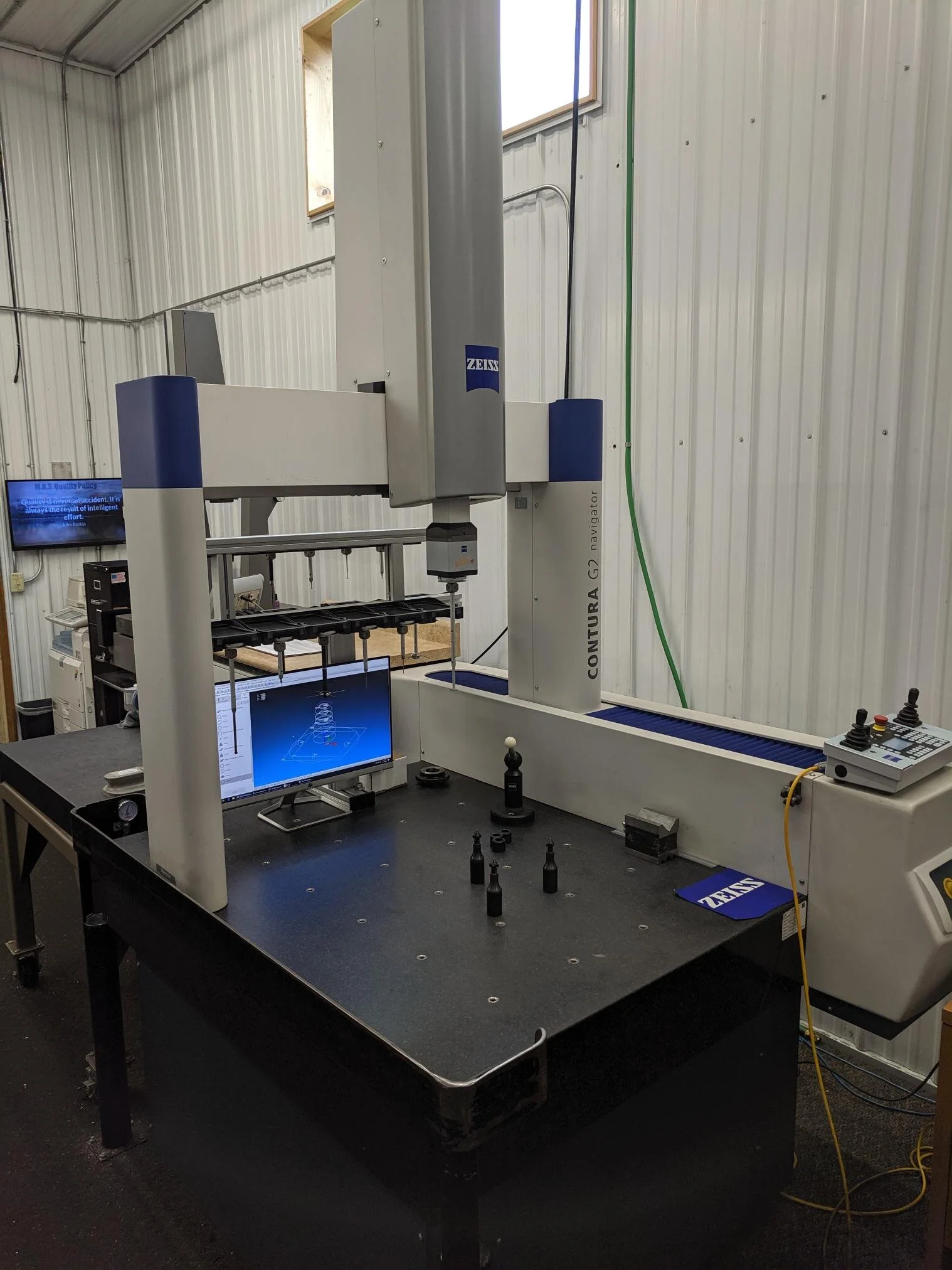

We ensure that your parts leave our facility in top-notch condition. Each part is hand-inspected and put through our rigorous quality control process. Tools used in the process include:

Optical Comparators

CMMs

Sunnen Gauges

Variety of Gauge Tools

Key Quality Equipment

Starrett HD400-M3 Comparator

Mitytoyo PH320 Comparator

Brown & Sharpe CMM MicroXCEL765

Zeiss Contura G2 CMM